PRODUCTION

Capacity of Filtered Ice

The flourishing success of Igloo Ice Sdn Bhd lies in the many strengths of our top management and teams which comprise operation, QA/QC, admin/finance and sales and marketing.

Through collaborative teamwork and forward-thinking initiatives, we will reach greater milestones and continue the effective maintenance of the FSMS certification.

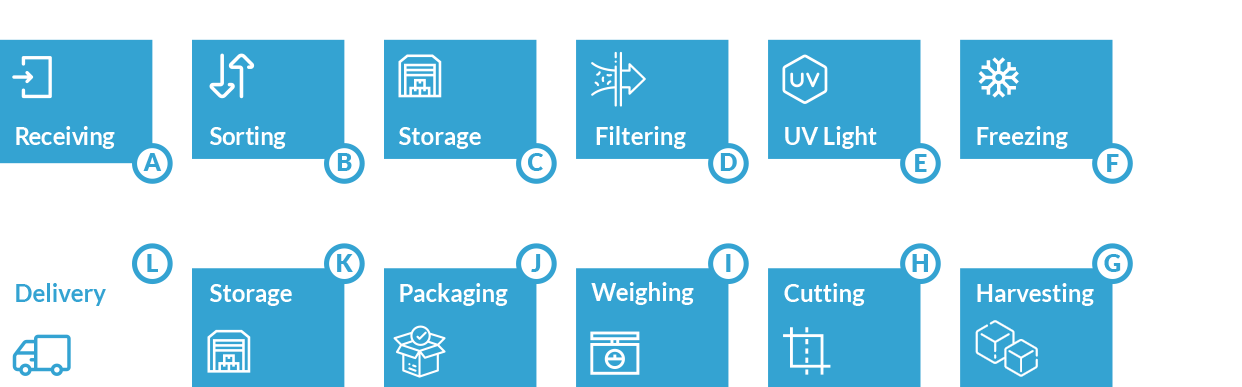

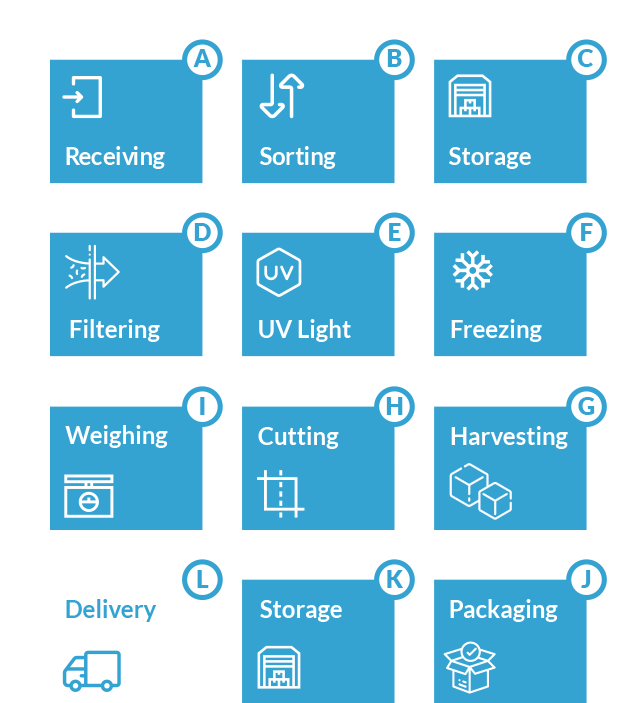

PROCESS FLOW

Process Flow

We have five operation lines that strigently adhere to the steps in accordance with the process flow. Every step is undertaken with utmost diligence and strict attention to detail.

PRODUCT SAFETY & QUALITY

You Can Trust

Aligned with our rigorous quality control, the Production Head of Department and Quality Assurance (QA) assures the maintenance of good control of the traceability of the product and quality. We ascertain that all operators are in excellent health and practise optimal personal hygiene. In June 2021, we carried out a new food safety training planning that applies to every production and operator.

We are determined to satisfy the requirements of the Ministry of Health and other relevant regulations and standards as follows

> Malaysia Food Regulations 1985

> Food Hygiene Regulations 2009

> MS 1514:2009 Good Manufacturing Practice (GMP) for Food (First Revision)

> MS 1480:2019 Food Safety According to Hazard Analysis and Critical Control Point (HACCP) System (Second Revision)

> Certificate of MeSTI (KKM)

> Certificate of Lesen Ice

> Certificate HALAL Malaysia (JAKIM)

> Certificate Ergonomics Trained Person Course (Initial Era)

Food Safety Policy

The top management of Igloo Ice Sdn Bhd has established a Food Safety Policy that is in line with the organisation's business goals and strategic direction, as well as the food safety requirements of the organisation itself, our customers and the authorities.

The policy shall be available, communicated, understood and applied at all levels within the organisation. A copy of it is displayed to promote external communication to interested parties such as customers, suppliers, contractors and auditors / inspectors from

authorities. Consistent with the intention of the policy, the top management shall ensure that food safety objectives are set and reviewed annually.

We are committed to producing and supplying safe products that meet FSMS, our customers' conditions and applicable legal requirements. This is achieved through these practices:

- Compliance to applicable food safety regulatory and statutory requirements.

- Fulfilling customers' product safety requirements.

- Food Act 1983

- Food Regulations 1985

- Food Hygiene Regulations 2009

- Fulfilling applicable product safety requirements.

- Providing a framework for establishing and reviewing the Food Safety Policy and objectives for our continuing effectiveness during management review meeting.

- Promoting effective internal and external communication throughout the supply chain, organisation and operation team.

- Continually improving our FSMS towards a preventive approach in reducing food safety hazards and consistency of product safety.

- Ensuring this policy is communicated, understood and implemented by all employees.

Food Safety Objectives

- To achieve 100% compliance of finished product heavy metal contamination as per Malaysian food regulations (14th schedule).

- To achieve 100% compliance of finished product microbiological contamination as per Malaysian food regulations.

- To achieve max 0 case of customer complaint pertaining to food safety and quality issue.

| BACTERIA | METHOD | COUNT PER 100ml |

| TOTAL COLIFORM |

Multiple Tube Method (37°c/48 Hours) |

Shall Not Exceed 10 (Most Probable Number) |

| Membrane Filter | Not More Than 4 Colonies Per 100ml |

|

| ESCHERICHIA COLI OR THERMOTOLERANT COLIFORM |

Multiple Tube Method |

Nil (Most Probable Number) |

| FECAL STREPTOCOCCI |

Membrane Filter | Nil in 100ml |

| PSEUDOMONAS AERUGINOSA |

Membrane Filter | Nil in 100ml |

| CLOSTRIDIUM PERFRINGENS |

Membrane Filter | Nil in 100ml |

| SULPHITE REDUCING ANAEROB |

Membrane Filter | Nil in 100ml |

Scope for Registration

Of Raw

Material

Of Finished

Products

Customers